Blog

Understanding Water-Based Anti-Seize and Its Uses

Automotive anti-seize compounds serve as a lubricant and seal to reduce wear on various parts. However, most are not water-resistant. You need a water-based anti-seize lubricant for applications that require protection from corrosion in wet or humid environments.

What Is a Water-Based Anti-Seize Lubricant?

Most anti-seize compounds are less effective in high humidity or wet conditions. Water-resistant anti-seize fills that void in the product line. It prevents parts from rusting or locking together from constant exposure to wet environments. These products are often referred to as:

- Thread lubricants

- Marine-grade anti-seize

- Water-based lubricants

- Saltwater anti-seize compounds

Even among the water-based anti-seize products, there are various levels of protection from corrosion.

Why Use Water-Based Anti-Seize?

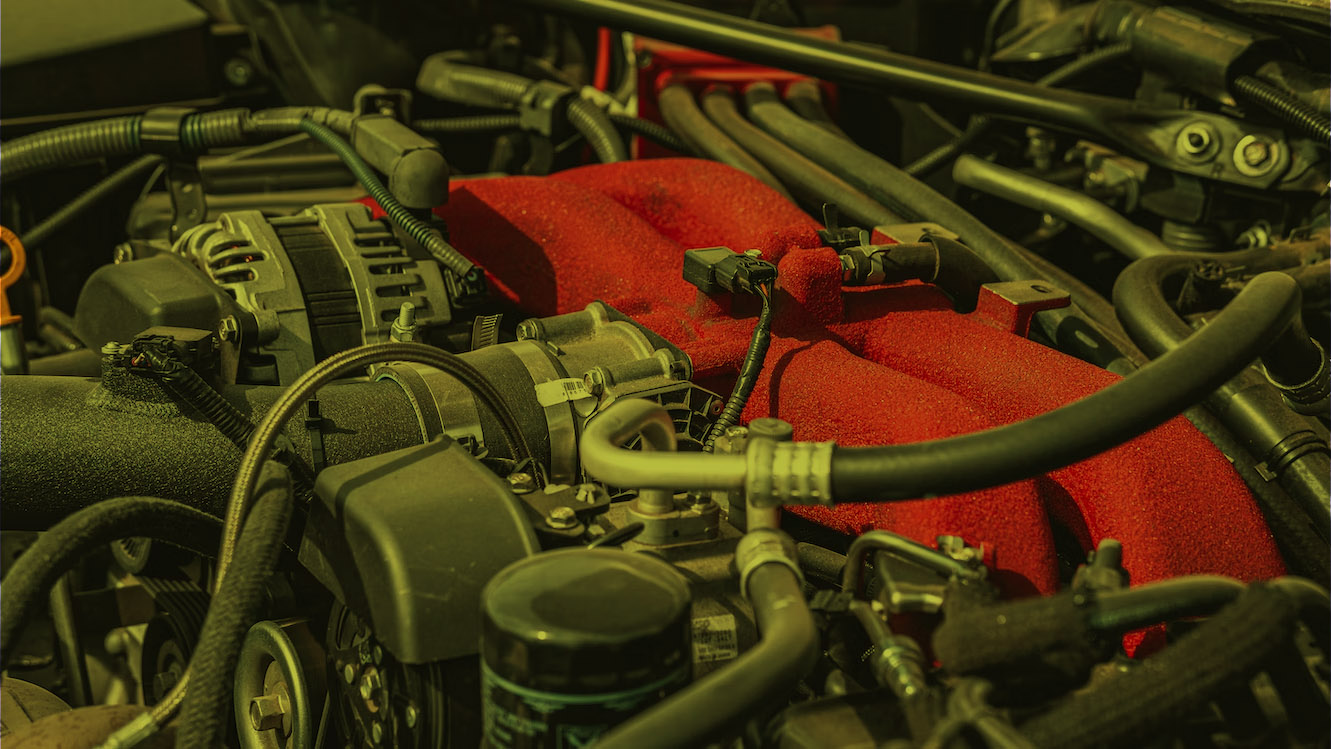

In the automotive industry, you rarely need an anti-seize lubricant that can withstand full water submersion. However, automobiles with exposure to highly humid or wet climates will benefit from water-resistant anti-seize compounds.

The marine-grade anti-seize formula protects assemblies highly exposed to fresh and saltwater. It provides the lubrication you need from an anti-seize compound without using metals and prevents water wash-out and galvanic corrosion.

Applications That May Require Water-Based Anti-Seize Lubricant

Some common applications for water or saltwater-resistant anti-seize lubricant include basic automotive parts:

- Dressing for water pump gaskets and flanges in the liquid cooling system of the engine

- Engine and housing fasteners

- Hatch covers and hinges

- Bolts and nuts, particularly in areas with significant exposure to contaminants and natural elements

- Mounting screws

Applying an anti-seize compound is a simple process that requires a clean surface and a brush applicator. Many anti-seize products come with a brush included, but there are spray applicators as well.

Features and Benefits of Saltwater Anti-Seize

Saltwater anti-seize lubricants have unique features and benefits for applications that require water resistance. Specific features include:

- Protects bolts, fasteners, flanges, and other metal interfaces in wet and humid conditions

- Can come with a brush-top applicator for easy use

- Reduces friction and increases the speed of disassembly

- Hinders galvanic corrosion between dissimilar metals

- Is non-hardening and non-dripping

Some anti-seize lubricants contain calcium sulfonate. This is a less expensive option for water resistance, and it can handle a wide temperature range, up to 350 degrees Fahrenheit. A more expensive option is calcium complex grease, which is more protective in wet and humid applications and can withstand higher temperatures, even up to 500 degrees.

Comparison to Metalic Lubricants

In addition to the unique features of water-based anti-seize lubricants, you want some general benefits that all anti-seize products provide, including versatility for small and large assemblies and compatibility with the type of material used. Water-based lubricant is efficient for many of the same applications for which you would use anti-seize compounds. However, metallic lubricants are essential for high-temperature parts that commonly exceed 500 degrees.

Finding the Best Water-Based Anti-Seize Lubricant

High-quality anti-seize compounds are crucial in automotive applications, and having a water-based anti-seize solution in your shop is essential for efficiency. For more anti-seize compounds to help prevent corrosion, check out our selection for American-made products to build an ideal workspace.

Sources:

- https://glueanswer.com/calcium-sulfonate-vs-calcium-complex-grease/

- https://www.nrc.gov/docs/ML1622/ML16221A272.pdf