Blog

Types of Drill Bits for Automotive Applications

It takes a lot of tools to successfully build, repair and restore vehicles, including drills and drill bits. These versatile tools make fast work of important tasks in automotive jobs so any mechanic must have a good drill and the right assortment of drill bits. Find out which drill bits are must-haves for your collection, how to use them and how to sharpen drill bits so they last.

Uses for Drills In Automotive Repairs

The first step in successfully using a drill in automotive applications is knowing when and why you should turn to this tool. Here are a few of the common applications:

- Drilling Holes: Drills are helpful for creating holes in many different materials found on a vehicle such as metal, plastic and fiberglass. These holes may be needed for running wires, creating drainage or mounting other components.

- Tapping Threads: After drilling a hole, a tap can be used with the drill to create threads inside the hole. That allows you to bolt or screw parts to the vehicle or repair stripped threads. Learning how to sharpen drill bits will make sure they are ready to cut a precise hole.

- Removing Rust or Paint: Attachments can add more usefulness to a drill. For instance, a wire brush attachment on a drill is a fast way to remove rust or paint before bodywork repairs. Other attachments can be used for polishing, cutting and riveting.

These are just a handful of ways a drill can help you get your work done in an automotive shop. By keeping your drill in good condition and your drill bits sharp, you can make short work of a lot of common tasks.

Types of Drill Bits and Their Uses

A drill is only as good as its bits and attachments. Getting the right drill bits allows you to approach any repair with confidence because you know you can take care of the job. Each of the following types of drill bit deserves a place in your toolkit.

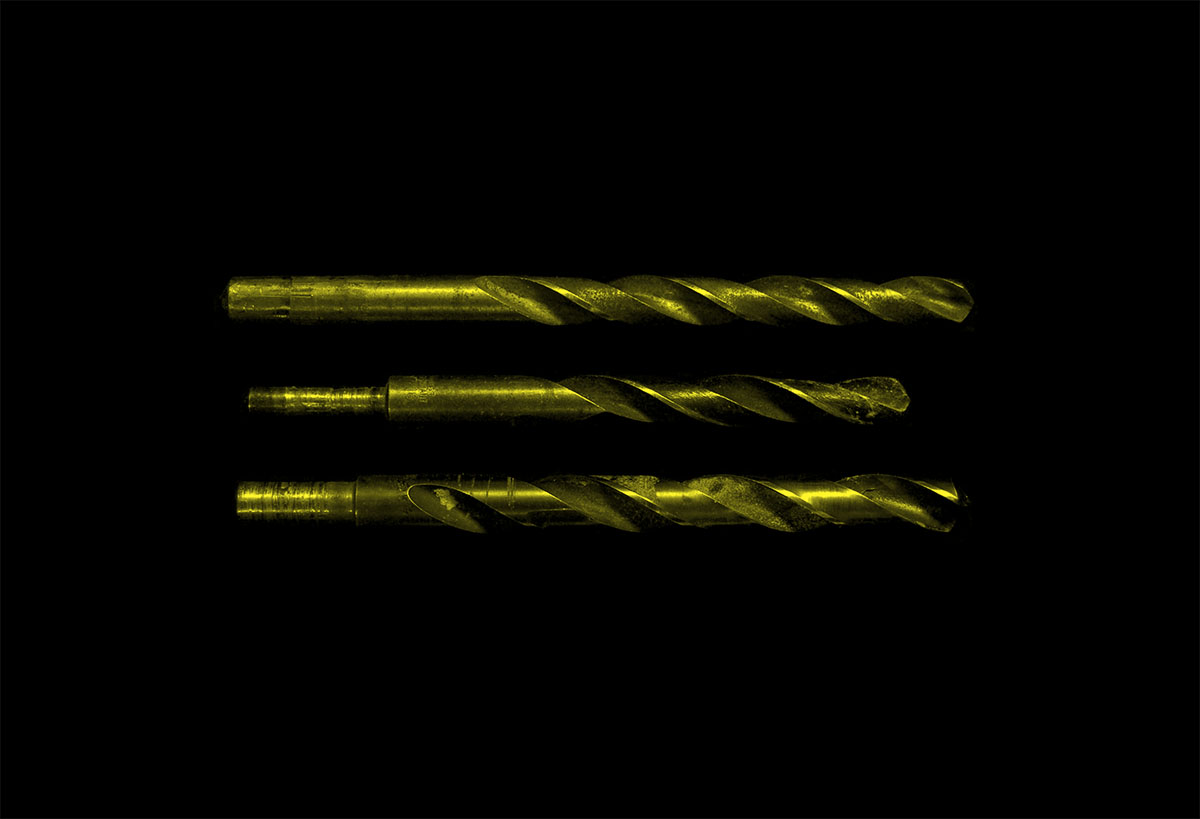

Jobber Drill Bit

The Jobber drill bit is one of the most versatile and commonly used drill bits in both automotive work and general applications. This drill bit has a long length compared to its diameter. It is designed to work on a wide range of materials, such as plastic, metal and wood. In automotive repairs, jobber drill bits are often used to make holes in different car components because the drill bit can reach far with precision. These holes can be used for engine parts, body panels and custom alterations.

Jobber drill bits are also useful for creating pilot holes, which are smaller holes drilled before a larger hole is made. Pilot holes give you control when preparing spaces for screws or bolts; you can make sure the fit is snug by starting with a smaller hole. The common sizes for jobber drill bits range from very small diameters, like 1 mm, up to larger sizes, around 13 mm or more, catering to a wide spectrum of automotive repair and customization needs.

Jobber drill bits come in right or left-handed orientations. You can choose the one you need based on the direction you need to drill in.

Step Drill Bit

Step drill bits are designed with a cone shape and multiple cutting edges. Each edge has a different diameter, and the sizes increase by measured steps along the length of the bit. This allows you to drill holes of various sizes without changing the bit. The graduated diameters on step drill bits make them incredibly useful in the automotive industry, especially for drilling through sheet metal or materials used in dashboards and other interior components.

These bits are particularly helpful thanks to their ability to enlarge holes cleanly and efficiently, which is much needed for custom automotive modifications and repairs, such as fitting aftermarket gauges, switches, or routing cables. Step drill bits commonly range from small sizes that start at about 3 mm to larger sizes up to 30 mm or more in diameter at the largest step. Learning how to sharpen drill bits of this shape can be tricky due to the rigid design.

Double-Ended Drill Bit

Double-ended drill bits are compact, dual-purpose bits designed for efficiency and convenience. These are good bits to have on hand since each end of the bit can be used for drilling. Once one end is at the end of its lifespan, you can flip it and use the other end, doubling the lifespan of the drill bit. Most mechanics use these drill bits for tasks that need speed and precision, such as drilling out broken bolts or screws without damaging the surrounding material.

Their compact size makes them good for working in tight spaces, a common scenario in automotive repairs. Common sizes of double-ended drill bits are usually in the smaller range, suitable for precise work, including sizes from 1/8 inch to about 1/4 inch.

Spot Weld Drill Bit

Spot welds are commonly used in automotive construction to join sheets of metal, but they can be hard to cut through when it is time to make repairs. That's where the spot weld drill bit comes in handy. This bit has a unique shape, allowing it to cut around the weld so surrounding parts can be removed with minimal damage. This is crucial in automotive bodywork repairs and restoration when preserving the integrity of the original metal is important.

Spot weld drill bits are used to take apart vehicle components and are perfect to keep around if you do a lot of bodywork. Common sizes of spot weld drill bits range from about 6 mm to 10 mm, tailored to the size of spot welds found in vehicles.

Having the right assortment of these drill bits puts you in a position to approach a repair with the right tool in hand so you get the best result. Make sure to get a variety of each type of bit so you have different lengths and diameters at the ready.

How To Sharpen Drill Bits

With your inventory of drill bits assembled, you need to make sure to take care of them. That includes sharpening your bits. Sharpening a drill bit is a crucial skill for anyone who frequently uses drills. Dull bits don't work well, leading to holes that are the wrong dimensions, more time spent working and potentially damage to the materials.

While it's not the most exciting task, sharpening drill bits is necessary if you want to get the full lifespan out of your parts. Sharpening drill bits on your own is cost-effective as well since you won't need to replace them as often. Take a look at how to sharpen drill bits, both with and without a bench grinder.

Understanding the Drill Bit

Before sharpening, it's essential to understand the parts of a drill bit. The most important areas are the tip and cutting edges. In these areas, you'll focus on maintaining two critical angles: the point angle and the relief angle. The point angle determines how the tip of the bit enters the material being drilled, while the relief angle is the slope of the cutting edge and determines how efficient the cutting is.

As you sharpen, you'll want to make sure you are restoring these two angles to their appropriate shape and slope. When you can no longer restore these angles with sharpening, the drill bit may have reached the end of its lifespan.

Sharpening With a Bench Grinder

- Safety First: Before you start, gather protective gear. Use protective eyewear to prevent sparks or metal filings from hitting your eyes, and consider wearing gloves and long sleeves as well.

- Prepare the Grinder: Place the bench grinder firmly on a stable surface. The grinder should have a fine-grit wheel for sharpening drill bits. Coarse grit wheels can remove too much material and damage the bit.

- Inspect and Clean the Drill Bit: Before sharpening, clean the bit with a brush to remove any debris. Examine the bit carefully, as dust and metal filings can become stuck in the grooves of the bit. Inspect the bit for any major damage. If the bit is damaged, it might be beyond sharpening.

- Set the Correct Angle: Check your grinder to see if there is an angle guide and set the wheel at the appropriate angle. If your grinder doesn't have a guide, use an angle gauge to set the wheel. The most common point angle for drill bits is 118 degrees.

- Sharpen the Cutting Edges: Holding the bit at the correct point angle to the grinding wheel, gently press the cutting edge against the wheel. Use light pressure and grind in short bursts to avoid overheating, which can make the steel brittle. If needed, dip the bit in water to cool it down if it becomes too hot to touch. Rotate the bit to sharpen the other cutting edge, ensuring both sides are equally sharpened. This balance is crucial for the bit to drill efficiently and straight.

- Check and Adjust: After sharpening, inspect the bit. Both cutting edges should be sharp and even. If necessary, make additional adjustments.

Remember, patience and practice are key to achieving the perfect edge. It may take a while to get your bit back to its original state, but having a quality cutting edge is worth the effort.

Alternative Methods

Not everyone has access to a bench grinder, but you still need to know how to sharpen drill bits. Other tools can be used to restore the angle on your drill bits as well:

- Drill Bit Sharpening Tools: Many manual and electric sharpening tools are available, designed specifically for drill bits. These tools often come with guides to help maintain the correct angle while sharpening.

- Angle Grinders: While less precise than a bench grinder, an angle grinder can be used with a fine-grit disc. The principle is the same, but it requires a steady hand and careful attention to angles.

- Diamond Files: For minor sharpening and deburring, a fine diamond file can be used to manually sharpen the cutting edges of a drill bit. This method is more time-consuming and requires a good eye for angles but can be useful for small adjustments.

Tips for Effective Sharpening

Sharpening drill bits requires careful attention to detail. You can't rush the process if you want to get a good result. Keep in mind that the effort you put in will impact the result, so remember these tips to get your bits to their best condition

First, make sure to be consistent as you sharpen your bits. Ensure that all matching cutting edges are sharpened to the same length and angle so the bit drills evenly. Next, be mindful of the temperature of the bits while sharpening. Let them cool completely before beginning sharpening and keep them cool while working on them. If you are new to drill bit sharpening, practice with older or less valuable bits first until you get a feel for how to sharpen drill bits.

You can also extend the life of your drill bits between sharpening by protecting them. Store them in a case that keeps bits from being jostled and tossed around. Bits that are thrown into tool boxes or storage bins without protection can get worn down faster, requiring you to sharpen more often and replace your bits sooner.

Remember, sharpening can't fix every drill bit. Bits that have been used for the wrong materials or applications could be damaged beyond repair. Examine your bits regularly to identify ones that need to be replaced.

Learn How To Sharpen Drill Bits and Have the Tools You Need

Different drill bits can make hard work in the automotive world a lot easier. Whether you need to create pilot holes or separate sheets of metal, the right drill bit can get the job done. By getting an assortment that meets your needs and learning how to sharpen drill bits, you can improve your efficiency in your shop. If there are types and sizes of drill bits missing from your collection, shop ROGO Fastener today.

Resources:

- https://apexindustrialsupply.com/blog/the-different-kind-of-drill-bits-according-on-the-type-of-industry/

- https://www.einhell.de/en/blog/workshop/how-to-sharpen-your-drill-bits-with-a-bench-grinder/

- https://monroeaerospace.com/blog/what-are-double-ended-drill-bits/

- https://www.builderonline.com/building/getting-to-know-your-drill-bits-a-quick-guide_o

- https://www.safetycompany.com/safetyblog/why-your-drill-bits-keep-breaking-/