Infographics

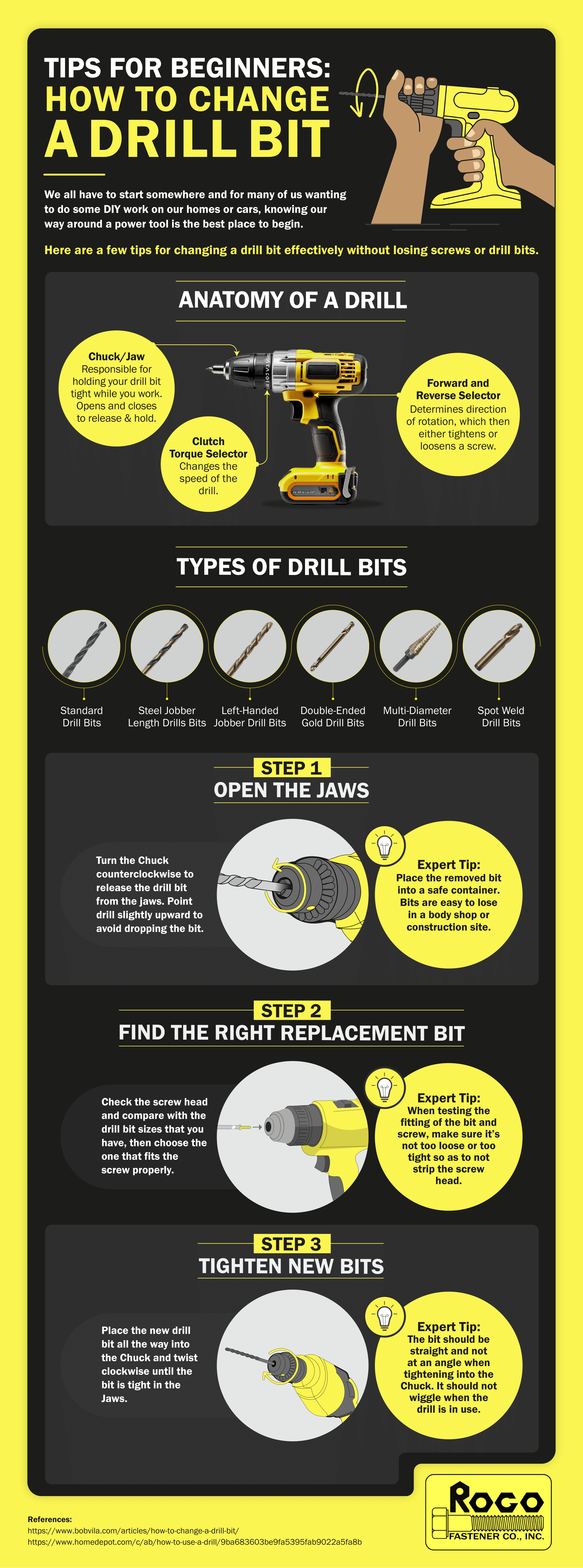

Tips for Beginners: How To Change a Drill Bit

We all have to start somewhere and for many of us wanting to do some DIY work on our homes or cars, knowing our way around a power tool is the best place to begin. Here are a few tips for changing a drill bit effectively without losing screws or drill bits.

- Anatomy of a Drill

- Chuck / Jaw

- Responsible for holding your drill bit tight while you work. Opens and closes to release and hold.

- Forward & Reverse Selector

- Determines direction of rotation, which then either tightens or loosens a screw.

- Clutch Torque Selector

- Changes the speed of the drill.

- Types of Drill Bits

- Standard Drill Bits

- Steel Jobber Length Drills Bits

- Longer than standard

- Left-Handed Jobber Drill Bits

- Double-Ended Gold Drill Bits

- Two sides keeps it lasting longer

- Multi-Diameter Drill Bits

- Spot Weld Drill Bits

- Step 1: Open the Jaws

- Turn the Chuck counterclockwise to release the drill bit from the jaws. Point drill slightly upward to avoid dropping the bit.

- Expert Tip: Place the removed bit into a safe container. Bits are easy to lose in a body shop or construction site.

- Step 2: Find the Right Replacement Bit

- Check the screw head and compare with the drill bit sizes that you have, then choose the one that fits the screw properly.

- Expert Tip: When testing the fitting of the bit and screw, make sure it’s not too loose or too tight so as to not strip the screw head.

- Step 3: Tighten New Bit

- Place the new drill bit all the way into the Chuck and twist clockwise until the bit is tight in the Jaws.

- Expert Tip: The bit should be straight and not at an angle when tightening into the Chuck. It should not wiggle when the drill is in use.

Drills are powerful and versatile tools, made even more useful by the option to use different drill bits. Each bit performs a special function and having a full set ensures a craftsman can tackle nearly any project. For people just getting started with a drill, it isn't always easy to know how to switch your bits. Thankfully, beginners can learn how to change a drill bit with a few tips.

Every make and model of drill is unique, so there may be small differences when working with a specific drill. Check the owner's manual and safety guide before starting to reduce the chances of breaking the drill or a drill bit. To get started switching out your drill bits, follow these steps:

- Perform a Safety Check: Drills are powerful and can be dangerous. Before attempting to change a drill bit, make sure the drill is unplugged and powered off to prevent the chance of electrical shock. If the drill was recently used, check that it is not hot and allow time for the metal to cool down.

- Open the Chuck: The chuck is the part of the drill that holds the jaws that clamp onto the drill bit, holding it in place. Causing damage to the chuck means your drill bit may not be secure so it is important to open it the right way.

There are two main types of chucks: keyless and keyed.

- Keyless chucks are common on many modern cordless power drills. The chuck can be loosened without using a special tool, or key. To open the chuck, grab firmly and rotate counter-clockwise (for most models). The chuck will come loose, allowing for the bit to be changed.

- Keyed chucks are designed to be unlocked with a special tool. That chuck key is inserted in designated holes on the chuck. Once turned counter-clockwise, the jaws will open enough for the drill bit to be removed.

- Take Out the Old Bit: Once the chuck is open, take out the bit that is no longer needed. Pull it straight out from the jaws. If it is stuck, try to open the chuck more. Once removed, store the bit in a safe place so it isn't lost or broken and is available for later use.

- Insert the New Bit: Holding the bit by the shank, which is the round smooth part, insert it straight into the chuck. Check that the bit is set properly in the jaws of the chuck.

- Tighten the Chuck: With the new bit in place, re-tighten the chuck around the bit to hold it in place. With a keyless chuck, you can use your hand or pliers to turn the chuck clockwise until it is tightened. For a drill with a keyed chuck, use the key to turn the chuck until the jaws are firmly holding the bit. Be careful not to overtighten the drill.

What Not To Do

There are also some things to avoid while learning how to change a drill bit:

- Yanking out stuck bits: If a bit gets stuck, don't try to yank it out or force it to come loose. Doing this could damage the chuck and the bit, making both less useful. Use pliers gently on the flat part of the shank or reverse the drill while carefully trying to remove it.

- Touching the cutting edges: Drill bits often have very sharp edges. Avoid touching these directly to prevent cuts and injuries.

- Leaving loosened bits in the chuck: Always make sure the bit is securely tightened in the chuck before using the drill. Using a drill with a loose bit can cause the bit to fly out and potentially cause injury or damage.

That's a simple overview of how to change a drill bit. When the new bit is in place, take a moment and test it out. Use the drill on a piece of scrap to make sure it is secure and properly aligned. After the test, adjust as needed.

Drill and Drill Bit Maintenance Advice

Now that you know how to change a drill bit, how can you make sure you're taking care of your drill and bits in general? Here are a few easy ways to keep your equipment in good condition.

Keep It Clean

After each use, take the time to clean off the drill. Use a dry cloth to wipe sawdust, dirt or grime off the surface of the tool. Stubborn residue such as grease may require a damp cloth or the use of a solvent, but be careful not to get liquid on electrical components. The space around the chuck and the jaws need cleaning too so debris doesn't accumulate and reduce the function of the drill.

Cleaning also applies to the drill bits themselves. After drilling, always remove the bit and brush away any debris with a soft-bristled brush or compressed air. A toothpick can also be used for stubborn bits of material stuck in the grooves of the bit.

Lubricate Moving Parts

Drills have important moving parts that can get stuck. Applying a small amount of light machine oil can keep gears free, reducing friction and preventing rust. Use oils specifically made to lubricate machinery and use a light amount to avoid buildup.

A small amount of lubricant is also useful for the drill bit. When drilling into harder materials like metal, a small drop of cutting oil or lubricant helps dissipate heat and reduces wear on the drill bit.

Check the Electrical Cord

For corded units, inspect the power cord on a regular basis for any nicks, breaks or signs of wear. Damaged cords pose electrical hazards. Chargers for battery-powered units also need regular inspections.

Inspect the Chuck

After learning how to change a drill bit, use the same instructions to access the chuck and inspect it on a regular basis. Examine the jaws and exterior of the chuck for wear, warping or rust. Damaged parts may require repair or even replacement.

Sharpen Dull Bits

Over time, drill bits will naturally become dull. Sharpening restores the cutting edges, improving the performance of the drill and the lifespan of the bit. Beginners may want to take bits to a professional for sharpening.

Proper Storage

When not in use, drills and all drill bits should be stored safely. Bits and drills that are tossed into toolboxes can get jostled, becoming damaged and dull. Use a case or organizer designed for drill bits.

Match the Bit to the Task

Using the wrong type of drill bit for a specific material can lead to poor performance and premature damage. Become familiar with the most common types of drill bits:

- Twist bits: The most versatile type, ideal for wood, plastic, and some metals

- Masonry bits: Designed for drilling into brick, concrete, and stone

- Multi-diameter bits: Increases thickness without changing bits

- Double-ended bits: Lasts longer as both sides can be used

- Spade bits: For drilling large holes in wood

- Jobber length bits: For softer materials like wood or softer metals

- Spot weld bits: Specific to spot welds in automotive applications

- Brad point bits: Leave a cleaner hole in wood thanks to a sharp center point

Remembering these maintenance tips in addition to knowing how to change a drill bit allows even a beginner to build amazing things with their power drill.

Learn How To Change a Drill Bit and Start Building

Knowing how to change a drill bit is a critical part of getting the full versatility of a power tool. With a bit of practice, beginners can switch bits as needed to work with different materials and create holes of different sizes. Shop with ROGO Fastener for all the drill bits you need.

Resources:

- https://www.bobvila.com/articles/how-to-change-a-drill-bit/

- https://www.youtube.com/watch?v=bFtjdLWA69Q

- https://www.homedepot.com/c/ab/how-to-use-a-drill/9ba683603be9fa5395fab9022a5fa8b

- https://www.thespruce.com/how-to-change-drill-bit-8363150

- https://www.euromarc.co.nz/resources/12-common-drilling-problems-and-how-to-avoid-them

- https://www.bobvila.com/articles/how-to-change-a-drill-bit/

- https://www.homedepot.com/c/ab/how-to-use-a-drill/9ba683603be9fa5395fab9022a5fa8b