Blog

Synthetic Anti-Seize Grease for Extreme Pressure Applications

Typical copper anti seize grease is excellent for most automotive applications. It provides superior lubrication, preventing corrosion, galling, and part damage under average conditions. However, extreme-pressure applications often require additives to perform those functions.

Factors That Affect the Type of Anti Seize Grease Needed

Extreme-pressure anti seize lubricants are often required even when pressure levels are not extreme. Other factors that contribute to wear and grease breakdown could necessitate a different product than you normally use. You must consider how it will be used to choose the right anti-seize.

Major factors that impact what type of anti-seize will work best in a situation include:

- Amount of pressure parts are under

- Level of friction

- Expected temperature range

- Type of metal

You must understand how each of these factors affects the others to make an informed decision. Then, evaluating that information will help you decide if you need to use a special anti seize grease for extreme pressure, such as one with graphite or molybdenum sulfide.

Extreme pressure situations often involve a combination of high temperatures, speeds, and friction loads; however, extreme friction loads alone can also necessitate special extreme pressure lubrication.

Unique Lubricating Needs of Extreme Pressure Applications

Common lubricants, including standard automotive anti seize grease, can fail under the following extreme conditions:

- High speed and extreme temperature

- Extreme pressure

- Extreme friction and high pressure

Unfortunately, many automotive components are regularly subjected to these conditions. For example, any exhaust components or those directly linked to the exhaust are exposed to extreme operating temperatures. Some of these parts can easily reach 1000 degrees Fahrenheit or more under normal use.

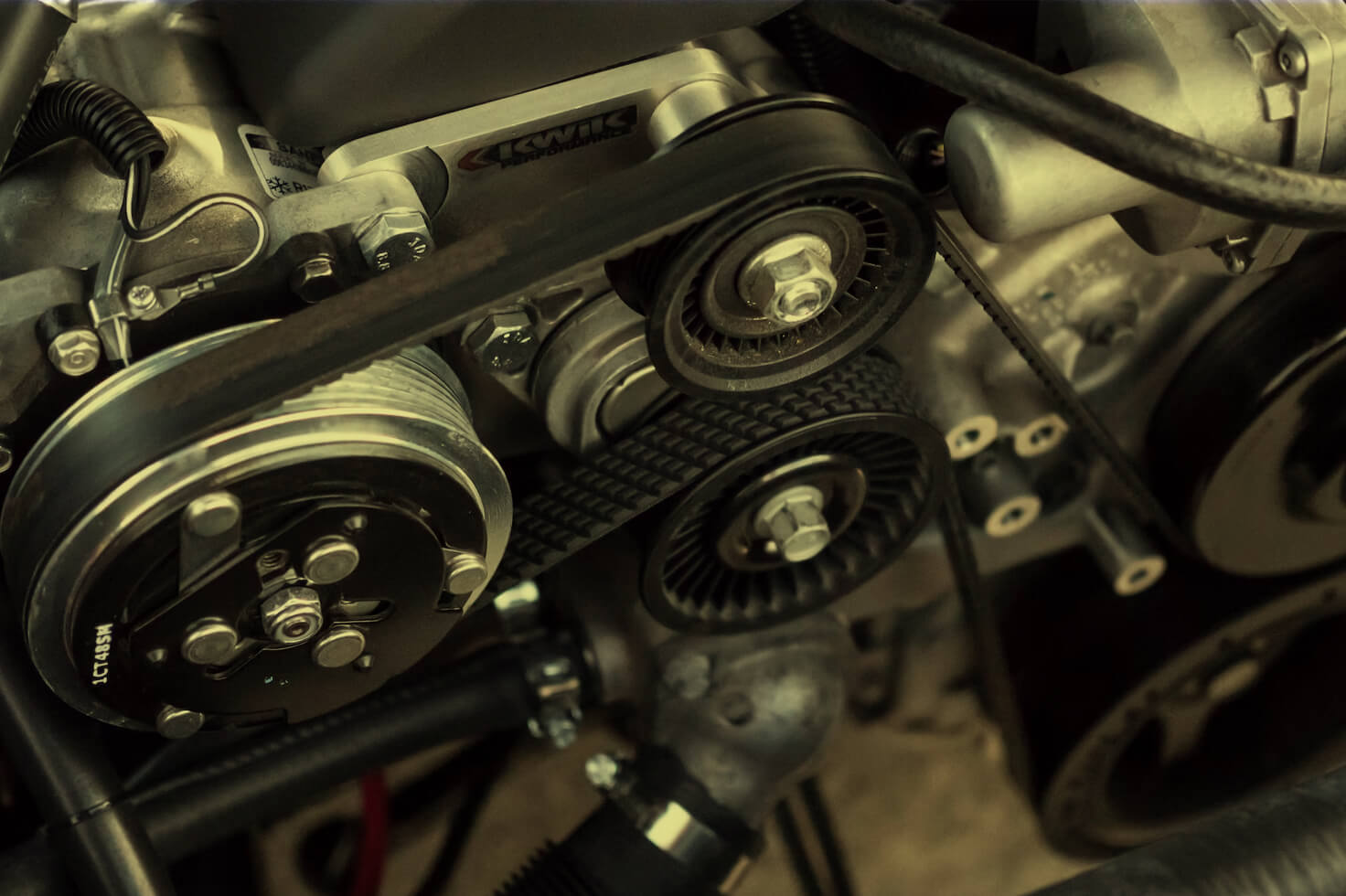

Moving parts with metal-on-metal contact, such as gearboxes, are subjected to incredibly high friction levels. These components will benefit from lubrication with special anti seize grease designed to handle extreme pressures.

Metal Alternatives in Anti Seize Grease for Extreme Pressure

Metal-based anti-seize grease is a repair shop standard. For example, copper performs exceptionally well in high temperatures and can be used in a wide range of repairs, including those with moderate amounts of pressure. However, connections that experience extreme pressure benefit from synthetic additives.

Graphite is one such product. Its unique crystalline structure lets each layer slide over the others. As a result, it offers superior lubrication under high mechanical loads. Graphite offers several advantages over many other types of lubricants, including:

- Excellent resistance to extreme pressure

- Able to withstand high temperatures (temperature resistance increases when graphite is treated to reduce oxidation)

- Treated surfaces remain dry, so they do not attract dust or contamination

- Forms an extremely strong bond to the surface substrate, increasing wear resistance

Molybdenum sulfide is another additive that can reduce friction in extreme pressure additives. Its structure is similar to that of graphite, and it is also incredibly slippery. This makes moly anti-seize products a popular choice.

Anti seize grease is a standard product in any auto repair shop. However, not all grease is made the same. When you need anti-seize for extreme pressure applications, turn to us. We sell professional-grade automotive products to ensure repairs meet customer expectations.

Sources:

- https://www.brighthubengineering.com/manufacturing-technology/73568-hydrostatic-lubrication/

- https://www.polytechnichub.com/extreme-pressure-lubrication/

- https://mechanicbase.com/engine/how-hot-does-an-exhaust-pipe-get/

- https://www.petro-online.com/news/fuel-for-thought/13/breaking-news/what-are-the-lubricating-properties-of-graphite/57615

- https://www.sciencedirect.com/science/article/abs/pii/S0043164821001836

- https://www.sciencedirect.com/science/article/abs/pii/B978044464313100003X