Blog

Multi-Purpose Anti-Seize Metal Treatment for Various Applications

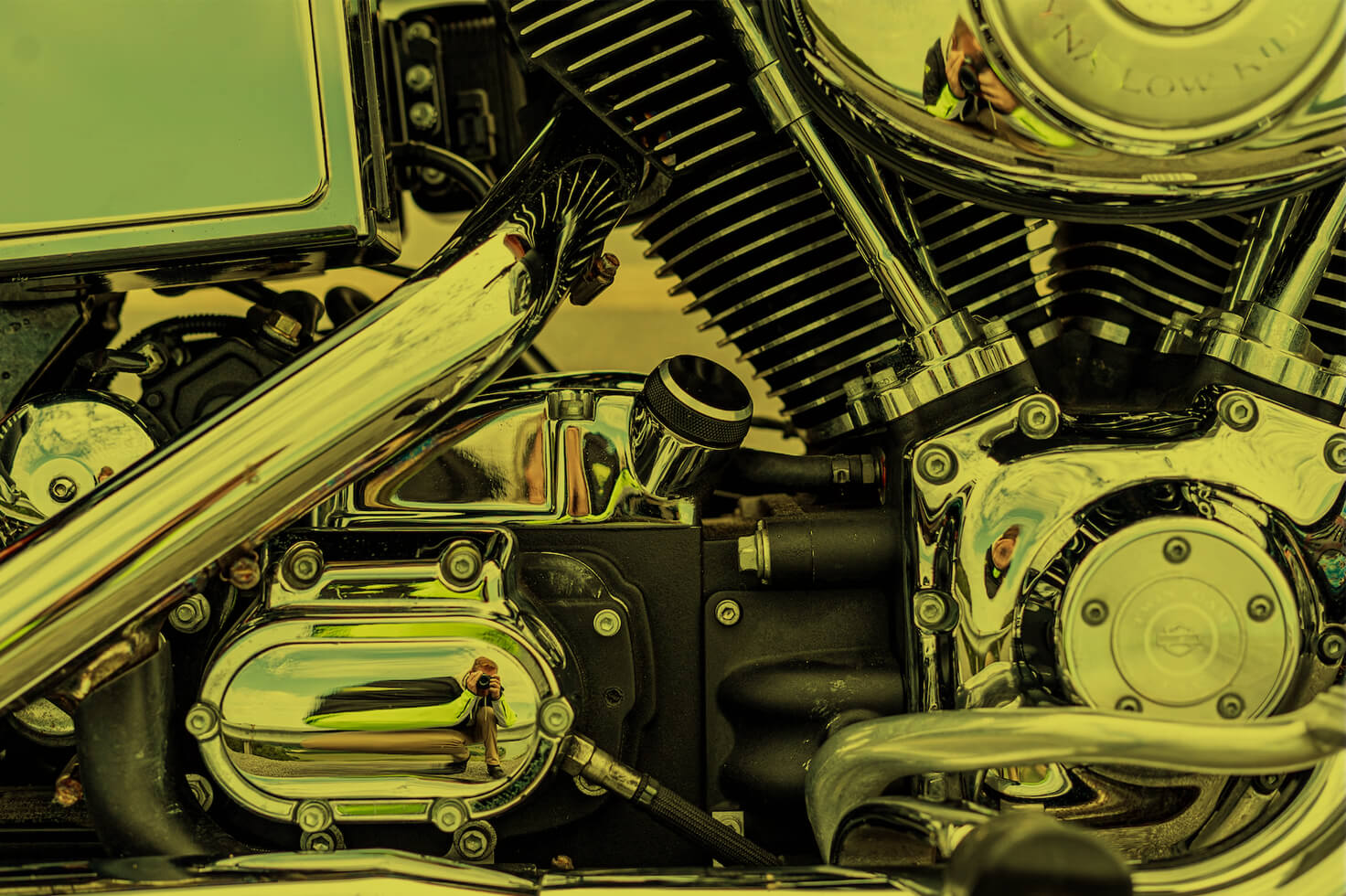

Metal surfaces are subject to wear from friction, pressure, and corrosion. A good multi-purpose anti-seize can help reduce these problems and ensure the proper functioning of metal parts.

Qualities of Multi-Purpose Anti-Seize

Mechanics have long applied anti-seize grease to automotive components. Unlike thinner lubricants, it contains solid particles that work well in high-pressure and friction situations. That makes it ideal for car systems such as brakes and suspensions.Exhaust and related engine systems can routinely reach 1,500 degrees or more, so its ability to withstand high temperatures is another excellent feature.

When shopping for a good all-around anti-seize grease, you want to keep a few things in mind. For example, a multi-purpose product may not be suitable for all applications. Check features such as working temperature range, type of applicator (spray, brush, squeeze tube, etc.), and compatible metals before choosing an anti-seize lubricant. A copper and graphite blend is often a solid choice since it retains function under a wide range of temperatures and can be applied to many different metals.

Functions of Multipurpose Anti-Seize

A high-quality anti-seize grease serves several important roles, including the following:

- Reducing wear from friction, heat, and contamination

- Preventing galling on threaded connections

- Minimizing friction between surfaces

- Limiting corrosion of metal surfaces, which are often exposed to extreme conditions

- Facilitating removal of treated parts. This is especially helpful on components such as brakes that require frequent maintenance or replacement.

- Lowering required torque to secure connections

Multi-purpose anti-seize lubricant can accommodate many of these functions on various surfaces. While it is most often used on threaded fasteners and connections, it can also be used in many other applications.

Anti-Seize for Metal Fasteners

Metal fasteners and threaded connections are prime places for anti seize metal treatment. When applied correctly it can help reduce wear and galling, prevent corrosion, and reduce friction. As a result of its functions, anti-seize makes removing treated parts easier. Therefore, it is commonly used on frequently changed automotive components.

Anti-seize grease also serves to reduce the torque needed to tighten connections. For that reason, you must reduce torque by the recommended percentage when tightening treated fasteners. An accurate torque wrench is an absolute must-have tool when working with anti-seize.

Mixed Metals

Pairing mixed metals is particularly troublesome. However, as automakers work to make cars lighter and more fuel-efficient, alternative materials such as special alloys, lightweight steel, and composites are being used more and more. While it achieves the goal of a lighter vehicle, it also creates problems as the materials react differently to environmental and operating conditions.

Using an anti seize for metal helps minimize problems associated with mixed metals. For example, it reduces the likelihood of a soft metal becoming damaged by a harder one. When anti-seize is used properly, you are less likely to experience wear and galling on mixed-metal connections.

Other Applications

You can also use multi-purpose anti-seize for various applications beyond threaded fasteners. For example, it is sometimes applied to battery terminals to reduce corrosion.

Anti-seize grease is a must-have product in any garage.Shop our store for multi-purpose anti-seize and other types of grease. We offer professional-grade shop supplies designed for tough applications.

Sources:

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8235354/

- https://www.sciencedirect.com/science/article/pii/S0264127522006165

- https://www.jdpower.com/cars/shopping-guides/how-hot-does-a-car-exhaust-pipe-get