DIY Tips for Beginners and Experts: How to Sharpen Drill Bits for Automotive Applications

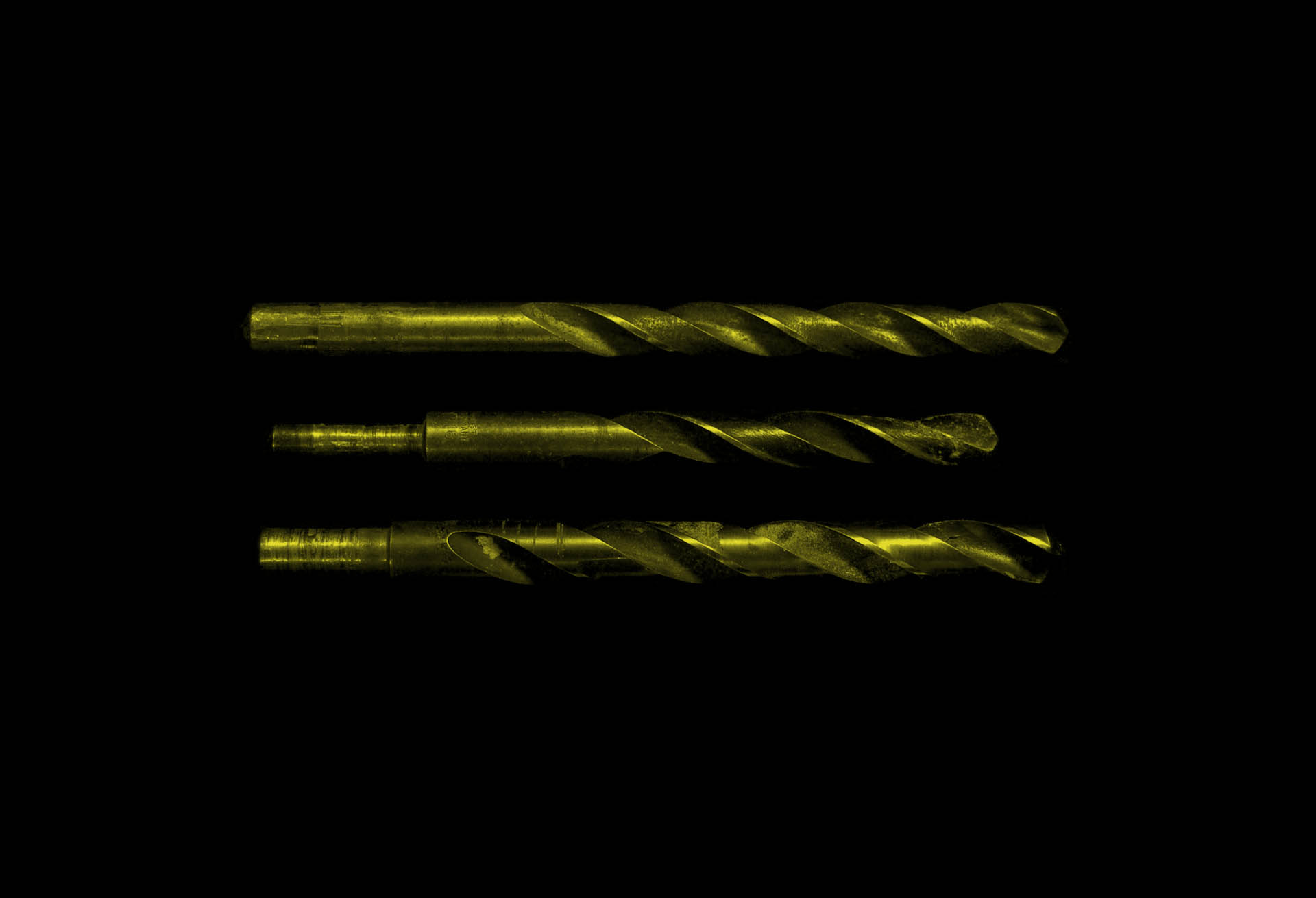

Sharp drill bits are vital automotive tools in any automotive professional’s arsenal.

Properly sharpened drill bits boost precision and efficiency. They also reduce overall wear and tear on the tools. By learning to properly sharpen drill bits, automotive workers reduce costs while improving their performance.

Do you know how to sharpen drill bits for automotive applications? Keep reading for easy-to-follow steps, safety tips, and advanced techniques to help sharpen and maintain drill bits effectively.

Do Your Drill Bits Need Sharpening?

Is it time to sharpen your drill bits? How do you know when your drill bits need sharpening? A few signs can clue you in:

- Dull Cutting Edges: When a drill bit’s edges appear rounded and blunt, it becomes difficult to cut through materials efficiently.

- Slow Drilling Speed: When a drill bit takes longer to penetrate materials, the change indicates a loss of sharpness and cutting efficiency.

- Excessive Heat During Drilling: Drill bits that generate more heat than usual can cause discoloration or smoke – both signs that the drill bit is struggling to cut.

- Poorly Formed Holes: Rough, uneven holes that are not the correct size can indicate the drill bit is no longer cutting cleanly.

Tools and Materials Needed to Sharpen Drill Bits

When you’re ready to sharpen your drill bits, you need to gather the proper tools and materials, including:

- Bench Grinder: A rotating abrasive wheel that is used for grinding and sharpening metal, a bench grinder is used for reshaping and sharpening drill bits.

- Drill Bit Sharpener: This specialized tool is used to hold and sharpen drill bits at the correct angle.

- Safety Goggles: Protective eyewear shields eyes from flying debris and sparks.

- Work Gloves: Gloves protect hands from sharp edges, heat and debris.

- Marker or Chalk for Marking Angles: Markers and chalk are used to mark the correct sharpening angle on a drill bit.

- Lubricant for Cooling and Reducing Friction: Use a cooling agent to reduce heat building on the drill bit and minimize wear.

Safety Precautions Before Sharpening Drill Bits

Sharpening drill bits can be dangerous between the sharp edges and heat-producing tools. Safety, therefore, must be a priority. Remember the following safety tips when sharpening drill bits:

- Wear Safety Gear: Wear safety goggles and gloves to protect eyes and hands.

- Ensure Visibility: Ensure the workspace is well-lit to see clearly.

- Boost Organization: Keep tools and materials organized to avoid tripping or slipping.

Drill Bit Sharpening Step-by-Step Guide for Beginners

Once you’ve gathered your materials and taken proper safety precautions, you’re ready to start sharpening your drill bits. Fortunately, a few simple steps can help you along the way:

- Prepare the Drill Bit: Get the drill bit ready by cleaning it with a cloth to remove dirt and debris. Once complete, inspect it for possible damage like cracks or chips.

- Use a Bench Grinder: Set up the bench rinder by adjusting its rest to match the drill bit angle Hold the drill bit to the correct angle – typically 60 degrees for standard bits. Then apply gentle pressure and rotate, evenly sharpening both cutting edges.

Use a Drill Bit Sharpener: Sharpen the drill bit by inserting it into the sharpener according to the manufacturer’s guidelines. Adjust the sharpener’s settings as needed, then test the sharpness by drilling into scrap metal.

Advanced Drill Bit Sharpening Tips and Techniques for Experts

No that you know the basics of sharpening drill bits, you can further “sharpen” your technique with advanced tips, including:

- Fine-tune The Drill Bit Angle: The proper angle ensures efficient cutting and a prolonged bit life. You can use a protractor or an angle gauge to adjust the angle manually.

- Sharpen Specialty Drill Bits: To sharpen speciality drill bits, try using a finer grinding wheel. Carbide-tipped drill bits can be sharpened using diamond grinding wheels for best results.

- Check and Maintain Symmetry: Make sure both drill bit cutting edges are symmetrical to prevent wobbling and ensure precise drilling. A drill bit gauge can help you verify the symmetry and make necessary adjustments.

- Polish the Cutting Edge: Once you’ve sharpened your drill bits, apply a fine abrasive or polishing wheel to smooth and refine your cutting edges, thereby reducing friction and improving cutting performance.

- Adjust Relief Angles: Optimize the performance of your drill bit on different materials by modifying the relief angles on its cutting edges. Doing so can improve your cutting efficiency and prolong the bit’s lifespan.

Maintenance and Care of Sharpened Drill Bits

Once your drill bits are good and sharp, you’ll want to maintain them for prolonged use. Properly store your drill bits using a drill bit case or holder, and make sure you store them in a dry place to prevent rust.

In addition to proper storage, you can care for your sharpened drill bits by cleaning them after each use, wiping them down with a cloth. Next you’ll want to apply light oil or specialized lubricant to prevent rust.

No matter how well you care for your drill bits, they eventually will need to be replaced. You’ll know when that time comes by signs of irreparable damage, including severe wear, chips and cracks.

Troubleshooting Common Issues with Sharpening Drill Bits

No matter how skilled you become at sharpening your drill bits, you’re bound to run into complications or obstacles at some point or another. Remember the following troubleshooting tips for common issues:

- Drill Bit Not Cutting Smoothly: When this happens, it could indicate your drill bit has dull edges, in which case you just sharpen it. However, you also might need to adjust the angle.

- Overheating During Sharpening: If your drill bit is overheating while sharpening, try using lubricant or coolant. You also should try to lighten the pressure you’re applying.

- Uneven Sharpening: If your drill bit is sharpening unevenly, make sure you are using a consistent angle and pressure. You also can try using jigs or guides for better results.

- Chipped or Damaged Edges: If your drill bit gets chipped or otherwise damaged, you might be using an incorrect grinding wheel or applying excessive pressure. Inspect your drill bit and replace it if the damage is too severe to repair.

- Loss of Cutting Performance: When your drill bit loses its cutting performance too quickly after sharpening, you might be using improver heating treatment or poor-quality materials.

You might consider upgrading to higher-quality drill bits or adjusting your sharpening technique. Consider the quality drill bits offered by Rogo Fastener Co.