Blog

A Comprehensive Guide on Automotive Fastener Standards

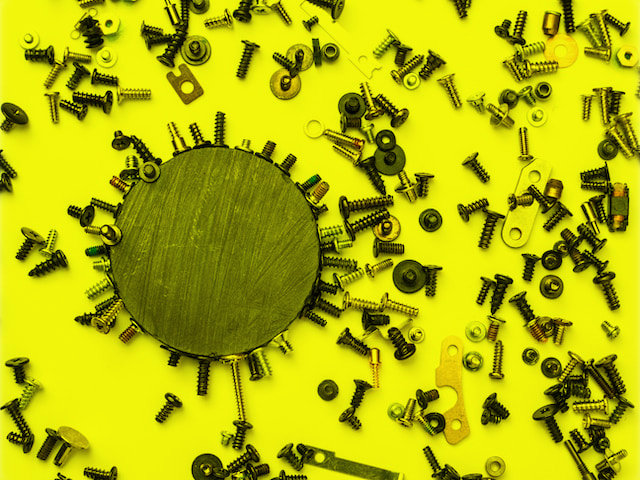

While they may seem modest, automotive fasteners are key players in automotive engineering. They help ensure the structural integrity and functionality of almost every part of the vehicle, making them indispensable. This is why different organizations have created fastener standards that ensure that every fastener is strong and secure.

Which Organizations Regulate Automotive Fasteners?

The whole automotive industry is ruled by strict standards that help guarantee the ideal performance of every vehicle. Standards for fasteners are just one of many regulations that help meet this goal. The International Organization for Standardization, and the Society of Automotive Engineers, among others, work to establish and enforce these important standards.

What Do The Standards Regulate?

Fastener standards include regulations on the materials used, fastener dimensions, testing procedures, and performance, for example, levels of stress and resistance.

Material Selection

Fasteners can be fabricated from a wide variety of materials, including:

- Steel or stainless steel

- Aluminum

- Iron

- Copper

- Alloys

- Zinc

- Plastic

The standards outlined by the ISO, SAE, and other organizations specify the specifications for the materials for each type of fastener, as well as corrosion resistance, durability, and strength requirements.

Dimensions

The dimensions of each fastener are also spelled out by fastener standards. Precision is key in automotive applications, so these standards mention the diameter, length, thread pitch, and other important dimensions for each type of fastener. These details matter and help guarantee the compatibility and interchangeability of various automotive components and brands.

Thread Design

Another aspect of fastener design covered by these standards is thread design. Threading provides both grip and stability for fasteners, and the form, angle, and pitch of the threading are essential for a stable connection. ISO and SAE standards help prevent mismatched threads and compromised structural integrity by regulating thread design.

Testing

Testing fasteners and fastener design is essential to the process. Fastener standards require many types of testing under different conditions to ensure reliability and strength. These may include torsion tests, tension tests, vibration tests, strength tests, and more. These are rigorous, allowing engineers to determine whether a certain design or material will withstand the stressful conditions found inside the workings of a vehicle.

Why Are These Standards So Strict?

Standards outline the minimum criteria that each automotive fastener must meet to be safe and functional. Can you imagine what would happen to a car made with substandard parts and fasteners? The minute it hits the road, it would begin to fall apart, parts would loosen or break under pressure, and the passengers could be injured.

Fastener standards not only exist for compliance purposes but as a way to constantly set the bar higher and reach toward a future of greater vehicle safety, reliability, and performance.

How Can You Ensure You’re Purchasing Quality Fasteners?

Reputable manufacturers always ensure that their products meet quality and design standards, and most exceed these expectations to ensure end-user safety. Reliable distributors, like us at ROGO Fastener, carry a wide selection of high-quality automotive fasteners and products for automotive shops and DIYers alike. Take a look at the products on our website.

Sources:

- https://rogofastener.com/product-category/fasteners.html

- https://rogofastener.com/page/blog/a-guide-to-automotive-clips-fasteners-types-materials.html

- https://www.engineersedge.com/fastener_thread_menu.shtml

- https://www.iso.org/obp/ui/#!iso:std:30971:en

- https://www.astm.org/products-services/standards-and-publications/standards/fastener-standards.html

- https://www.fastenersdata.com/iso-standards/iso-fastener-standards/